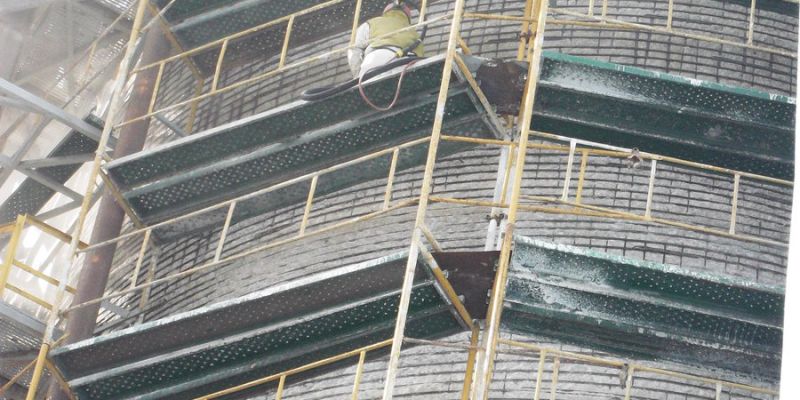

The project was conducted by ENKA’s experienced personnel, certified for working at height and for steel welding.

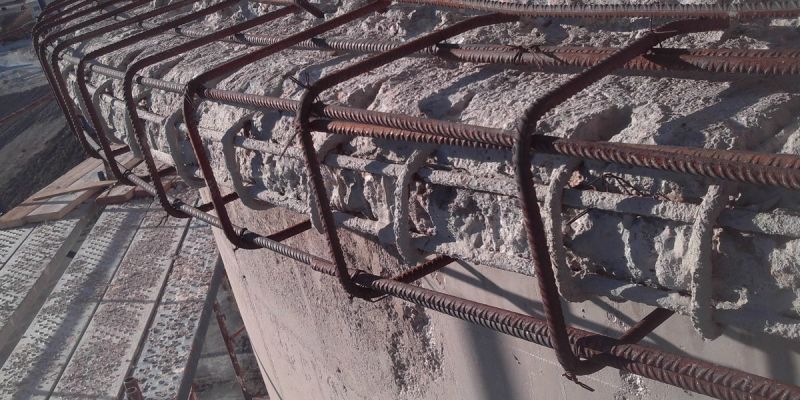

The works that took place were the following: setup of safe access at the interior of the silo funnel, installation of hoisting equipment for personnel and machinery, cutting of the existing anti-friction sheet metal Hardox 400 of 20mm thickness and removal of the segments using crane (approximately 120m2 total surface), removal of the bauxite beneath the funnel (approximately 300m3) manually as well as by using special equipment, repair of the concrete surface of the silo and of the funnel base plate, installation of new steel beams and kicker braces for the support of the new funnel, construction and installation of the new funnel, Hardox 400 with 25mm thickness, steel connection and welding at the interior of the silo, connection of the funnel using chemical anchors on the circumferential concrete walls, encasements construction and installation of vibrators.